Project Description

Features

Mutil-Spring, Unbalanced, O-ring pusher

Rotary seat with a snap ring holds all parts together in a unitised design which eases installation and removal

Torque transmission by set screws

Conform with DIN24960 standard

Recommended Applications

Chemical industry

Industrial pumps

Process pumps

Oil refining and petrochemical industry

Other Rotating Equipment

Operating range

Shaft diameter: d1=18…100 mm

Pressure: p=0…1.7Mpa(246.5psi)

Temperature: t = -40 °C ..+200 °C(-40°F to 392°)

Sliding velocity: Vg≤25m/s(82ft/m)

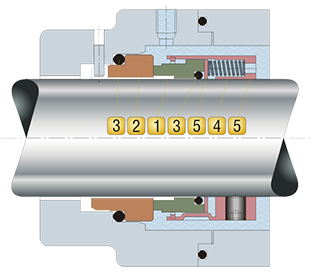

Product Structure

Combination Materials

1.Rotary Face

Silicon carbide (RBSIC) O

Tungsten carbide W1

Carbon graphite resin impregnated Ak

2.Stationary Seat

99% Aluminium Oxide B1

Silicon carbide (RBSIC) O

Tungsten carbide W1

3.Auxiliary Seal

Fluorocarbon-Rubber (Viton) V

Ethylene-Propylene-Diene (EPDM) E

PTFE Enwrap Viton M1

4.Spring

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G

5.Metal Parts

Stainless Steel (SUS304) F

Stainless Steel (SUS316) G